Sustainability

At M-Levy, sustainability means practical actions and continuous improvement across all areas of production. We are committed to making our operations more environmentally sound, providing a safe and pleasant working environment for our employees, and ensuring long-term financial stability. These principles are realized through concrete measures reflected in both daily decisions and long-term investments.

Optimizing energy use and energy-efficient investments

Our factory operates entirely on renewable electricity, and we closely monitor energy consumption. Reducing energy use relative to the scale of our operations is a key goal, and we have invested in energy-efficient solutions. For instance, we’ve replaced older hydraulic machines with servo-driven ones, significantly reducing the energy consumption of our equipment.

The specific heating ratio decreased by 20.5% from 2022 to 2023. In practical terms, this means we have heated a larger area using the same amount of energy. Despite recent expansions, our overall energy consumption has remained nearly unchanged.

The facility upgraded its lighting to LED technology. In addition to improving energy efficiency, this upgrade has enhanced workplace safety and created a more pleasant environment for our employees.

Minimizing material waste and efficient recycling

Recycling materials and efficiently utilizing resources are central principles of our operations. In 2023, our factory achieved a 92% recycling rate, with only 8% of waste being non-recyclable.

We use advanced software in raw material processing to optimize metal cutting, significantly reducing material waste. This enables precise resource usage and minimizes excess waste.

In-house waste compactors improved plastic and cardboard recycling by enabling the handling of larger waste volumes and enhancing waste management logistics.

Over the years, we’ve made numerous investments and expanded our operations significantly. What started as a two-man metal workshop has grown into a 6,000-square-meter production facility employing approximately 50 metal industry professionals across three locations as of 2024.

More sustainable heating and logistics solutions

To reduce energy consumption, we have focused on the energy sources used for heating our facilities. We heat two of our facilities with district heating, and in 2019, we converted a third property from oil heating to water and air heat pumps to reduce heating-related emissions.

In logistics and transportation, we have invested in environmentally friendly equipment. For internal logistics, we utilize electric forklifts that are energy efficient and emission-free during operation. Our vehicle fleet predominantly consists of electric and hybrid vehicles, with 91.7% of all logistics equipment currently being electric or hybrid-powered.

We also encourage staff adoption of electric vehicles, supported by five charging stations and an employee charging benefit.

In Year

2019

M-Levy transitioned one of its properties from oil heating to water and air heat pumps

Our heating ratio decreased by 20.5%

20,5%

from 2022 to 2023

Our factory’s recycling rate is

92%

We use

100%

100% carbon dioxide-free electricity at all our facilities

We listen to our customers’ sustainability needs

We believe in being a flexible partner, which is why we actively listen to our customers’ needs and requests. For instance, we have provided customers with detailed manufacturing data to help them conduct their own emissions calculations.

Additionally, we implement necessary operational changes and purchases based on the feedback we receive.

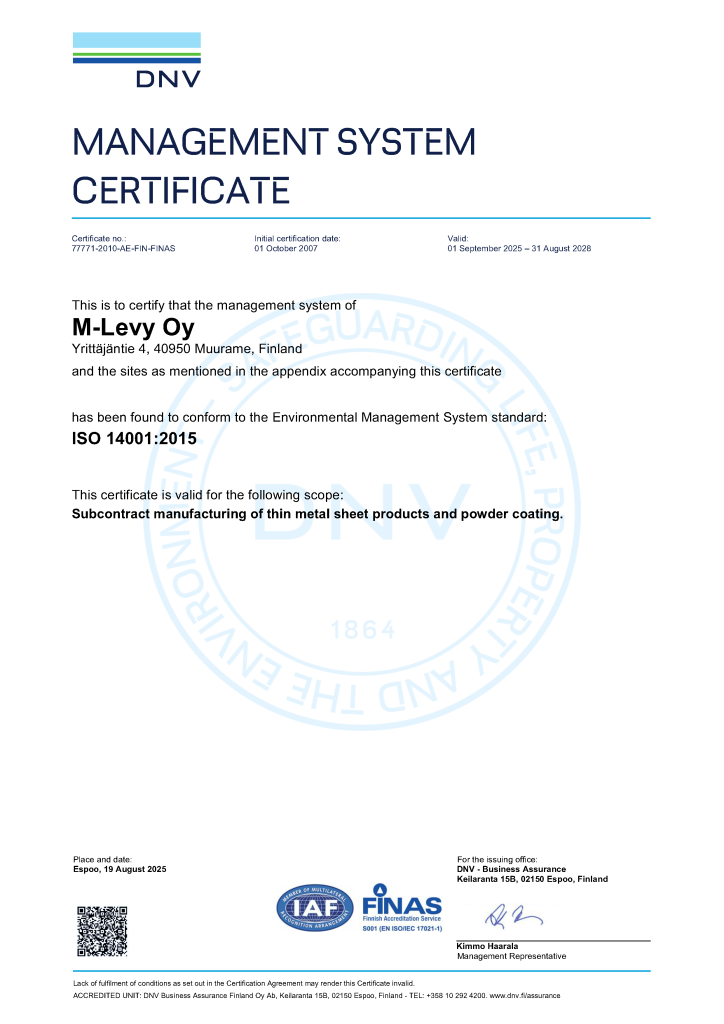

ISO certifications as the foundation of sustainable and quality operations

Our operations hold the ISO 14001:2015 environmental certification. This demonstrates that environmental considerations are systematically integrated into all processes. It requires us to continually assess the environmental impact of our activities and to drive continuous improvement.

The ISO 14001:2015 system supports both our energy and logistics solutions, ensuring that our operations adhere to the highest environmental standards.

We have also received the ISO 9001:2015 quality certification, which validates the high quality of our operations.

Employee wellbeing and safety

Our employees are the core of our operations, and their safety and wellbeing are paramount. Safety is a key consideration in the factory environment; for example, we have designed separate safety solutions for laser welding areas to ensure optimal working conditions.

We support employee wellbeing by offering benefits related to sports, culture, and wellness. Additionally, ergonomic tools, such as electric desks and anti-fatigue mats, support workability and improve daily comfort.

According to our employee wellbeing survey, our employees perceive our workplace community positively and consider the goals we set to be clear, realistic, and reasonable.

Finance as part of responsible operations

Without a sustainable financial foundation, we cannot invest in environmentally friendly solutions, employee wellbeing, or production development. M-Levy’s long history and stable customer relationships demonstrate that we have successfully created a reliable and sustainable business model that supports both our customers’ and our own growth. Responsible financial management requires the ability to adapt to changing circumstances and make bold, long-term decisions.

We have successfully navigated challenging economic situations, such as the 2008 financial crisis, and continued investing in initiatives that reduce environmental impact and improve working conditions.

A stable economy provides security for our employees and enables long-term development projects. It also allows us to respond quickly to customer needs and offer them responsible solutions.

M-Levy’s responsibility in the future

Although we have already taken several actions toward sustainability, we know that development is an ongoing process. We aim to further reduce our environmental impact by improving energy efficiency and introducing new innovations.

An external party will conduct a detailed study of our SCOPE 1 and SCOPE 2 emissions during 2025 to identify concrete areas for improvement and provide clear data on our carbon footprint.

The wellbeing of our employees and the development of workspaces are also central to our operations. We believe that a healthy work community is the foundation of a company’s success, and we invest in ensuring that our work environment meets both current and future needs.

We are already doing the right things, but we aim to become even better for the benefit of the environment, our employees, and our customers.