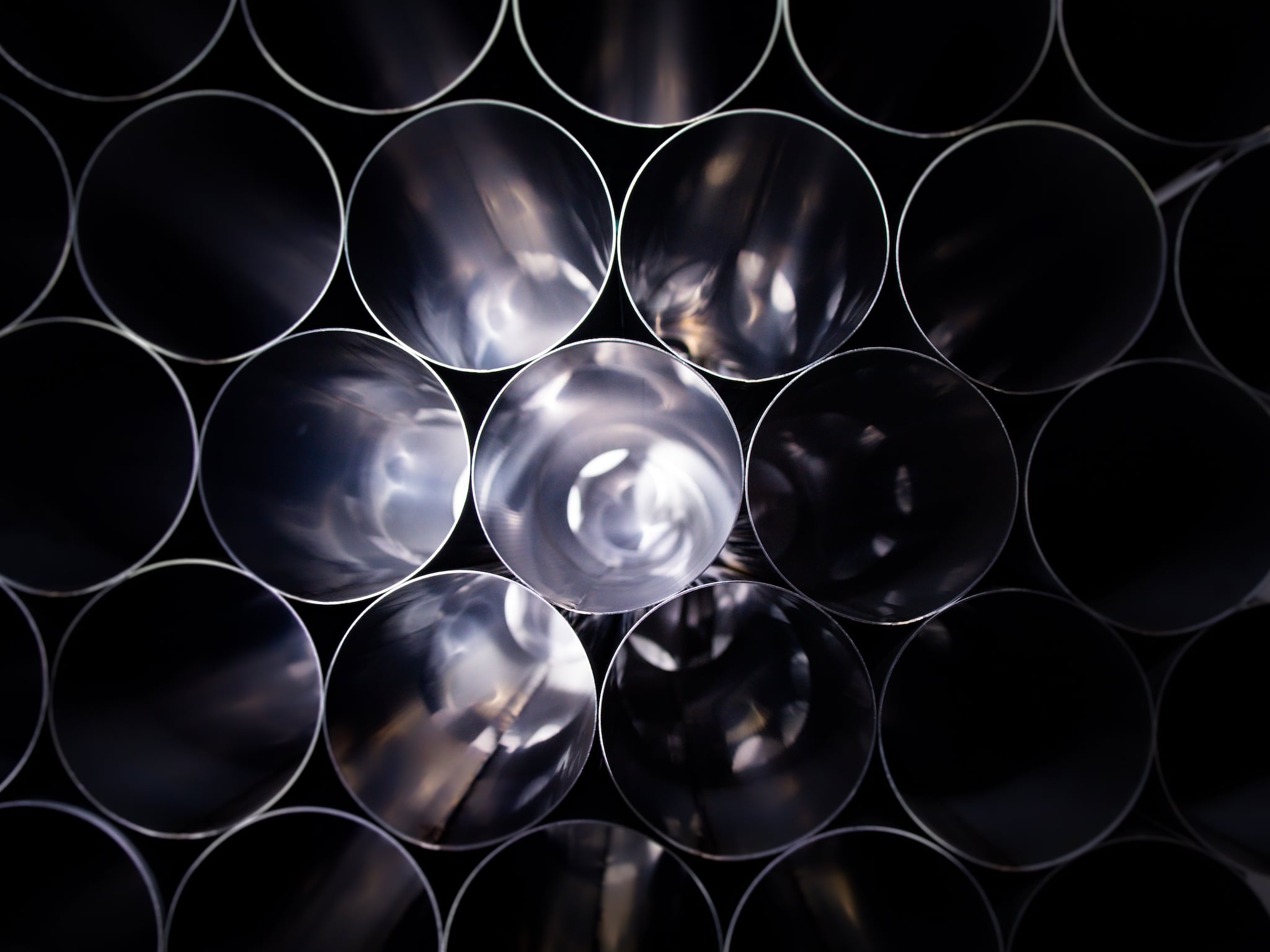

Cylinder manufacturing

Serial production of precise cylindrical components is our specialty

Are you looking for high-quality subcontracting services for metal products? With over three decades of experience in metalworking, we also specialize in cylinder manufacturing. Our skilled staff, extensive experience, and versatile machinery allow us to produce high-quality products tailored to your needs.

For cylinder manufacturing, we utilize plate rolling machines, seam welding automation, and grooving machines, ensuring parts meet your exact specifications.

Thanks to our comprehensive service offering, we can manage the entire production process, providing turnkey solutions including final packaging. We proactively support our customers with product development!

Sheet metal rolling

Plate rolling, also known as sheet rounding, is one of the most common sheet metalworking methods, where a metal sheet is formed into the desired shape using a rolling machine. With this machinery, we can produce cylinders, semi-circles, and other curved shapes. Rolling stiffens the sheet structure and is a relatively fast method of processing.

At M-Levy, we can roll parts with a maximum width of 2000 mm and a maximum sheet thickness of 4 mm.

Automatic seam welders

Our automated process welds the longitudinal seam of the pipe using the TIG method with shielding gas. This automation ensures the quality and repeatability of the seam, enabling efficient production of even larger batches. Our automated seam welding machines mainly produce pipes, casings, and cylinders.

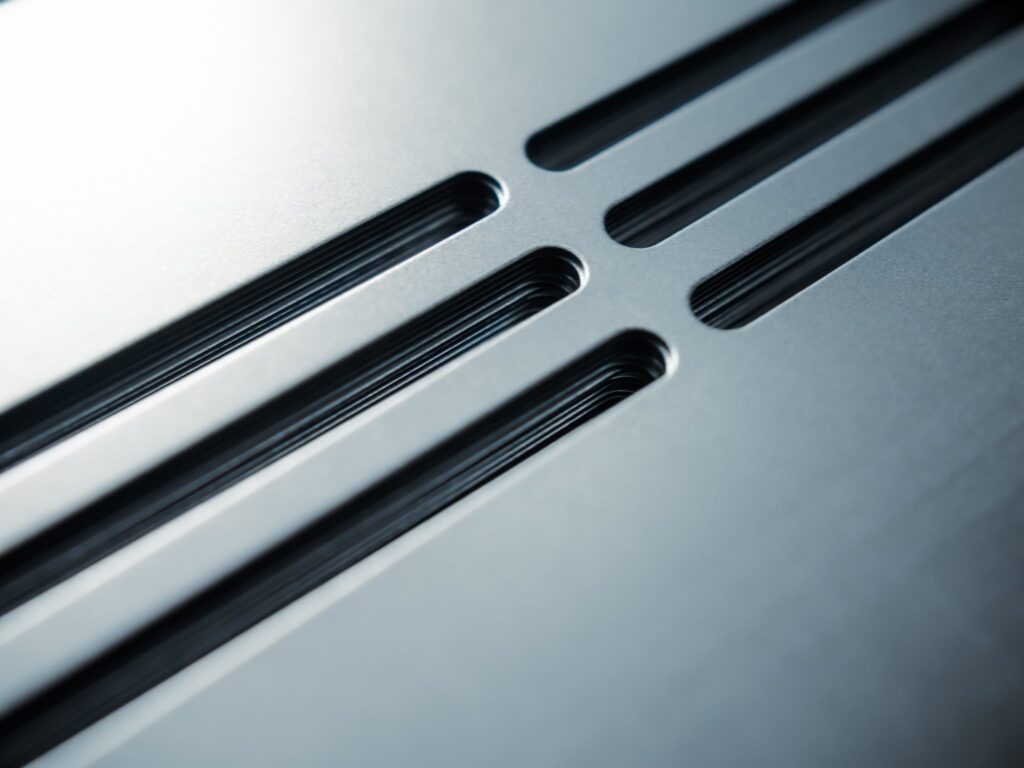

Grooving machines

We are equipped to create shapes and grooves in cylindrical parts. We have supplied, for example, over a million catalyst shells to the automotive industry, meeting strict dimensional tolerances and weld seam quality requirements. Our sales team is available to consult on the possibilities of shaping your cylindrical components.

Why choose M-Levy as your manufacturing partner for metal products?

Honest and clear communication

Transparency is the core of our business. We believe that open communication is the foundation of trust and long-term partnership. We keep you fully informed about your project’s progress at every stage. Furthermore, we take a proactive approach: if we identify a more efficient or cost-effective manufacturing method for your product, we will recommend it immediately.

Experienced professionals

Our team consists of top professionals with decades of experience in contract manufacturing. This experience ensures that we understand how to manufacture metal products effectively. If you wish, we are also happy to assist you in designing new products.

Comprehensive services

We provide all the services needed for sheet metal processing under one roof. Our facilities are equipped with automated bending, tube lasers, powder coating lines, and assembly services. This integrated approach saves you time and simplifies your supply chain.

Serving customers across the EU

Our office and factory are located in Muurame, Central Finland, near Jyväskylä, but we have satisfied customers from the West Coast to Eastern Finland. Our logistics network allows us to serve customers efficiently throughout the European Union.

Services

Contact us to find the best solution for your needs

Would you like to learn more or request a quote? Submit your request directly online, call us, or send an email, and we will be happy to answer any questions you may have.

Are you looking for a partner who can handle the entire process—from cylinder manufacturing to powder coating and final assembly? Read more about our service capabilities below!

Metal Laser Cutting and Punching

Laser cutting is a precise and rapid method suitable for cutting virtually all metals.

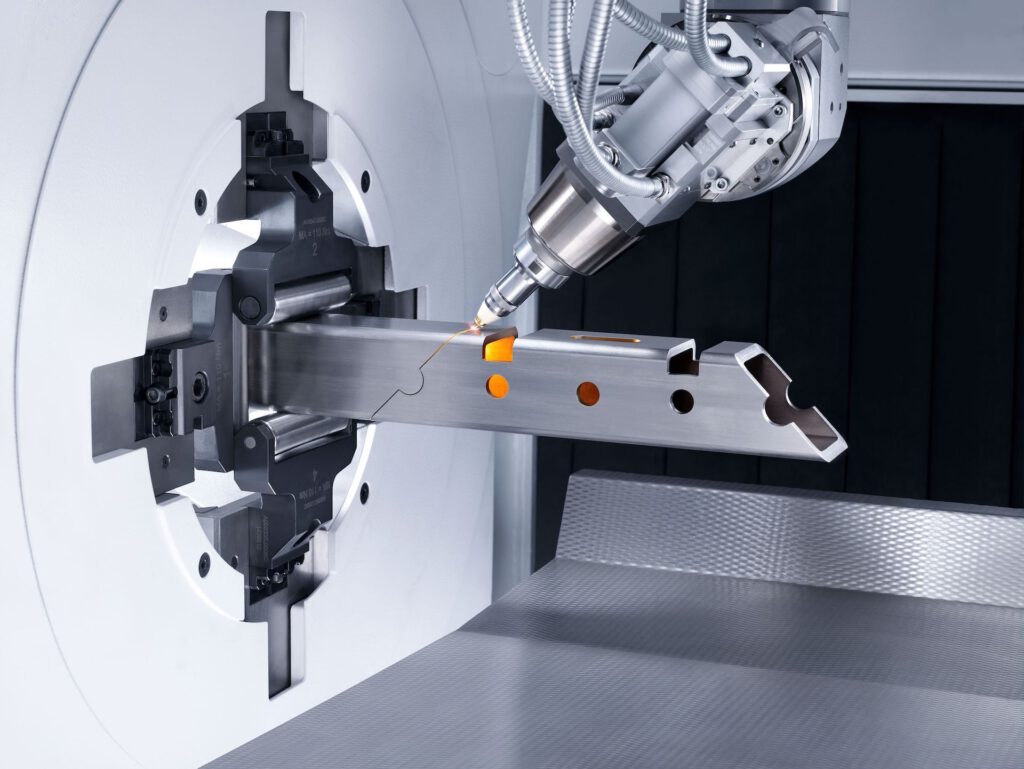

Tube Laser Cutting

Our tube laser machinery is equipped with versatile features designed to meet high expectations for quality, production speed, and cost-effectiveness.

Powder Coating

Powder coating provides a durable and visually appealing finish quickly, efficiently, and in an environmentally friendly manner.

Other Services

We also offer a range of additional processing services, including fastener insertion, eccentric pressing, and various finishing treatments.

Do you still have questions?

Contact us, and let’s discuss your needs in more detail!