Metal laser cutting and punching

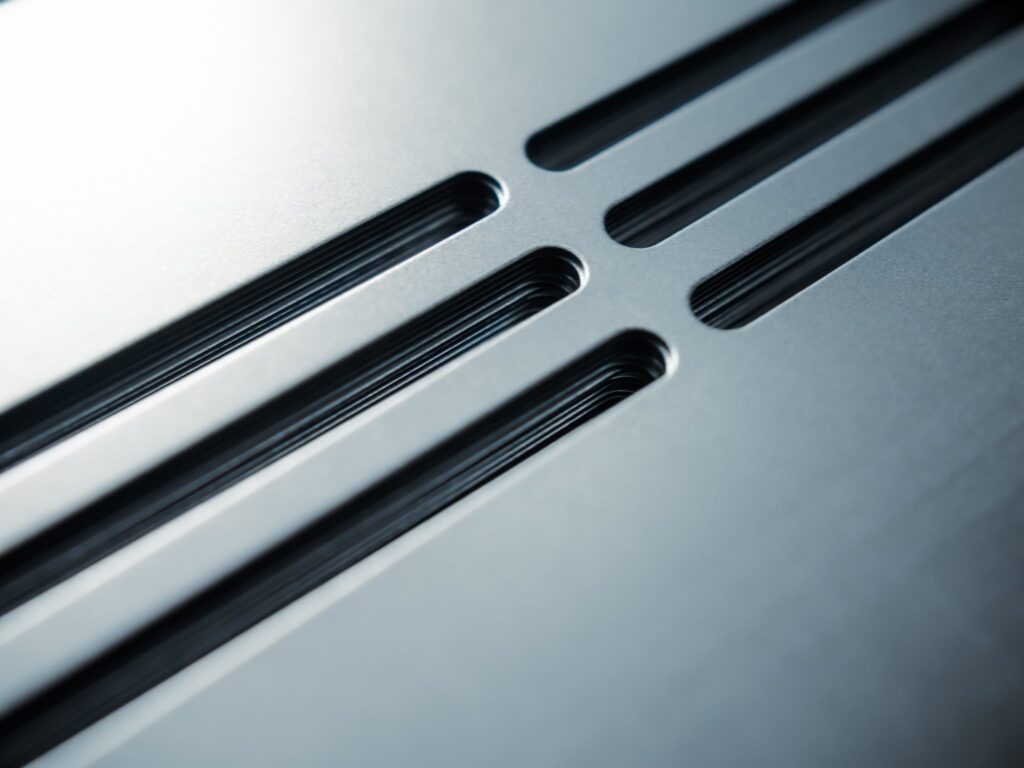

Almost all metals cut precisely and quickly

Are you looking for a partner for metal laser cutting and punching? With our versatile and modern machinery, we deliver both large and small production batches with high quality. Our facility is equipped with three 2D laser cutting machines, a punching and laser combination machine, a 3D tube laser, and a turret punch press suitable for thin sheet punching. This extensive capacity ensures we achieve the precise result you need.

We can deliver fully finished metal products, including final packaging. Our comprehensive in-house capabilities make this possible: we cut, bend, weld, and assemble metal products and structures. We also manage the warehousing and logistics of the final products.

Thanks to our extensive experience, we support you starting from the product development phase, ensuring optimal manufacturability and high-quality execution.

When you order from us, you can be confident that every product meets strict quality standards. Our experienced professionals ensure quality, while our cutting-edge, highly automated machinery guarantees cost-efficiency.

“M-Levy responds excellently to the changes we require and to rapidly emerging needs, such as new products or services.” – Tuomo Kakkonen, Production Director, Harvia

Laser cutting

Laser cutting is our primary method for manufacturing metal blanks and components. It enables rapid and flexible production, ranging from single prototypes to large-scale industrial series. Laser cutting is suitable for most metals, including structural and wear-resistant steel, stainless steel, aluminum, and non-ferrous metals such as brass and copper.

We have specialized in laser cutting since the 1990s, building our expertise on decades of practical experience. Our facility currently operates five cutting machines, utilizing both fiber and CO2 laser technologies.

Our equipment includes both fiber and CO2 lasers. Our latest fiber laser features 10 kW of power, allowing us to cut materials up to 25 mm thick. We also provide comprehensive post-processing for cut parts, such as edge rounding and grinding, tailored to your specific needs.

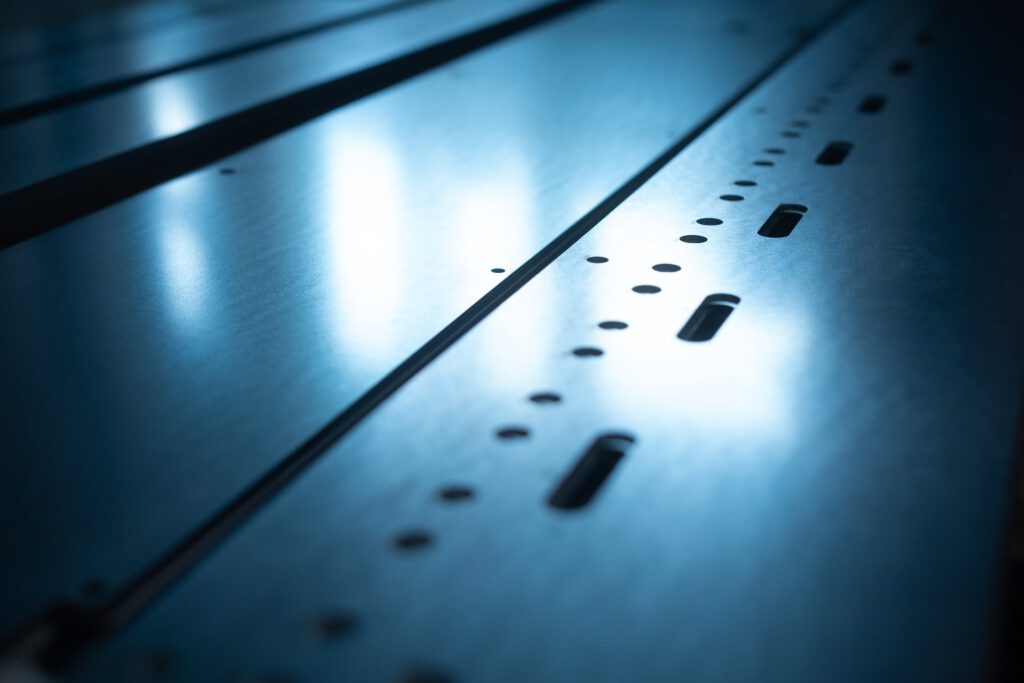

Punching

For punching, we have two machines equipped with automation systems: a CNC turret punch press and a punch-laser combination machine that enables both punching and laser cutting. Both machines also feature loading and unloading automation.

Beyond standard cutting, these machines allow for versatile processing of thin sheet metal, including countersinking, tapping, and various forming operations. We are committed to cost-efficiency; for specific projects, we are ready to invest in specialized tooling to accelerate production and optimize the manufacturing process.

Material Stock

Our material stock covers the most common sheet metals in various thicknesses, and if needed, we can source special materials on a per-order basis. We guarantee full material traceability and provide all necessary material certificates and quality documentation as required. Additionally, we keep a stock of spring steel at our facility.

Materials and maximum thicknesses

- Overall thickness range: 0.1 – 25 mm

- Cold-rolled steel: 0.5 – 3 mm

- Structural steel: 4 – 25 mm

- Stainless steel: 0.5 – 20 mm

- Aluminum: 0.5 – 20 mm

- Brass and copper: max 10 mm

- Spring steel: 0.1 – 4 mm

Machine capacity

Total laser/punching machines: 5 units

Max. working area: 1500 x 3100 mm

Why choose M-Levy as your manufacturing partner for metal products?

Honest and clear communication

Transparency is the core of our business. We believe that open communication is the foundation of trust and long-term partnership. We keep you fully informed about your project’s progress at every stage. Furthermore, we take a proactive approach: if we identify a more efficient or cost-effective manufacturing method for your product, we will recommend it immediately.

Experienced professionals

Our team consists of top professionals with decades of experience in contract manufacturing. This experience ensures that we understand how to manufacture metal products effectively. If you wish, we are also happy to assist you in designing new products.

Comprehensive services

We provide all the services needed for sheet metal processing under one roof. Our facilities are equipped with automated bending, tube lasers, powder coating lines, and assembly services. This integrated approach saves you time and simplifies your supply chain.

Serving customers across the EU

Our office and factory are located in Muurame, Central Finland, near Jyväskylä, but we have satisfied customers from the West Coast to Eastern Finland. Our logistics network allows us to serve customers efficiently throughout the European Union.

Contact us to find the best solution for your needs

Would you like to learn more or request a quote? Submit your request directly online, call us, or send us an email, and we will respond to questions you may have.

Services

Are you looking for a partner who can offer not only metal laser cutting and punching services but also a wide range of other services required for metal product manufacturing?

Read below to learn more about the services we offer!

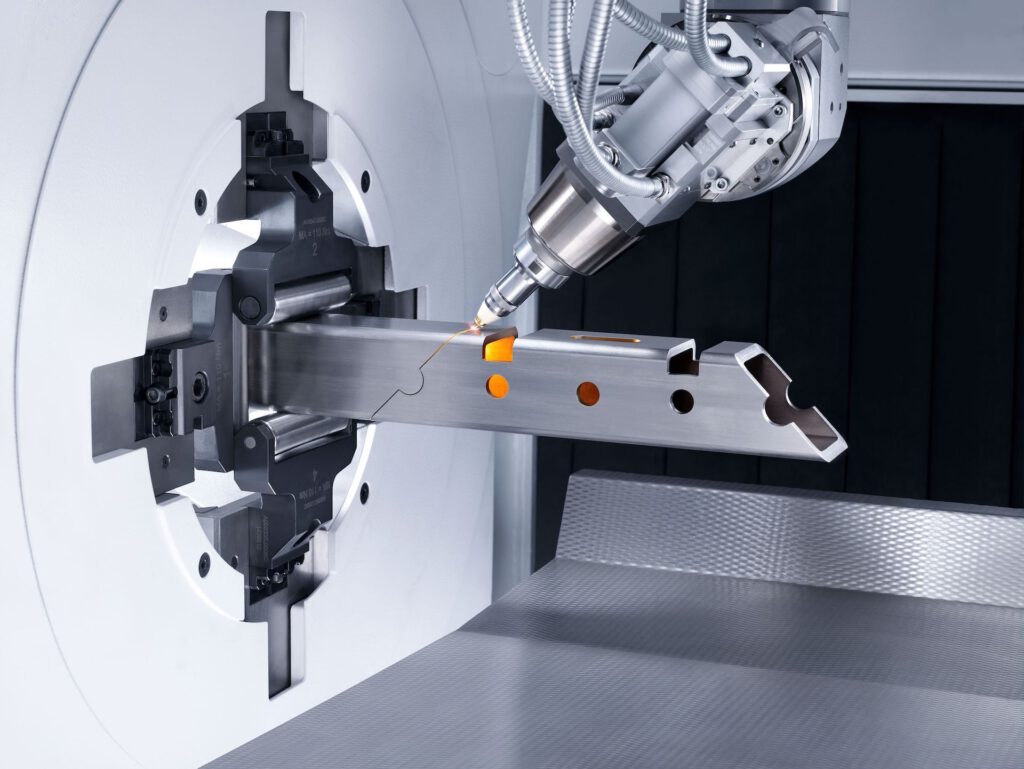

Tube Laser Cutting

Our tube laser machinery is equipped with versatile features designed to meet high expectations for quality, production speed, and cost-effectiveness.

Cylinder Manufacturing

Cylinder manufacturing is a core area of our expertise, backed by decades of experience.

Powder Coating

Powder coating provides a durable and visually appealing finish quickly, efficiently, and in an environmentally friendly manner.

Other Services

We also offer a range of additional processing services, including fastener insertion, eccentric pressing, and various finishing treatments.

Do you still have questions?

Contact us, and let’s discuss your needs in more detail!