Sheet metal bending

Accurate bending of sheet metal blanks, either with automated bending machines or manually with a press brake

Do you need a reliable partner for bending sheet metals? At M-Levy, we provide metal sheet bending tailored to your needs. You can easily incorporate our bending services as part of your product manufacturing process, but we also offer bending as a standalone service if needed. We manufacture sheet blanks either by laser cutting, punching with a turret punch press, or using a combination of these technologies.

We bend all types of metals and plastic sheets according to your needs. Our production capacity handles everything from single pieces to series of thousands.

Our experienced professionals always ensure the quality and dimensional accuracy of the bending process, so you receive precisely bent parts that meet your needs. We continuously invest in our machinery and tool selection to ensure our equipment supports the production of high-quality end products.

With our extensive experience, we can support you during the product development phase, ensuring the success of the bending process in practice!

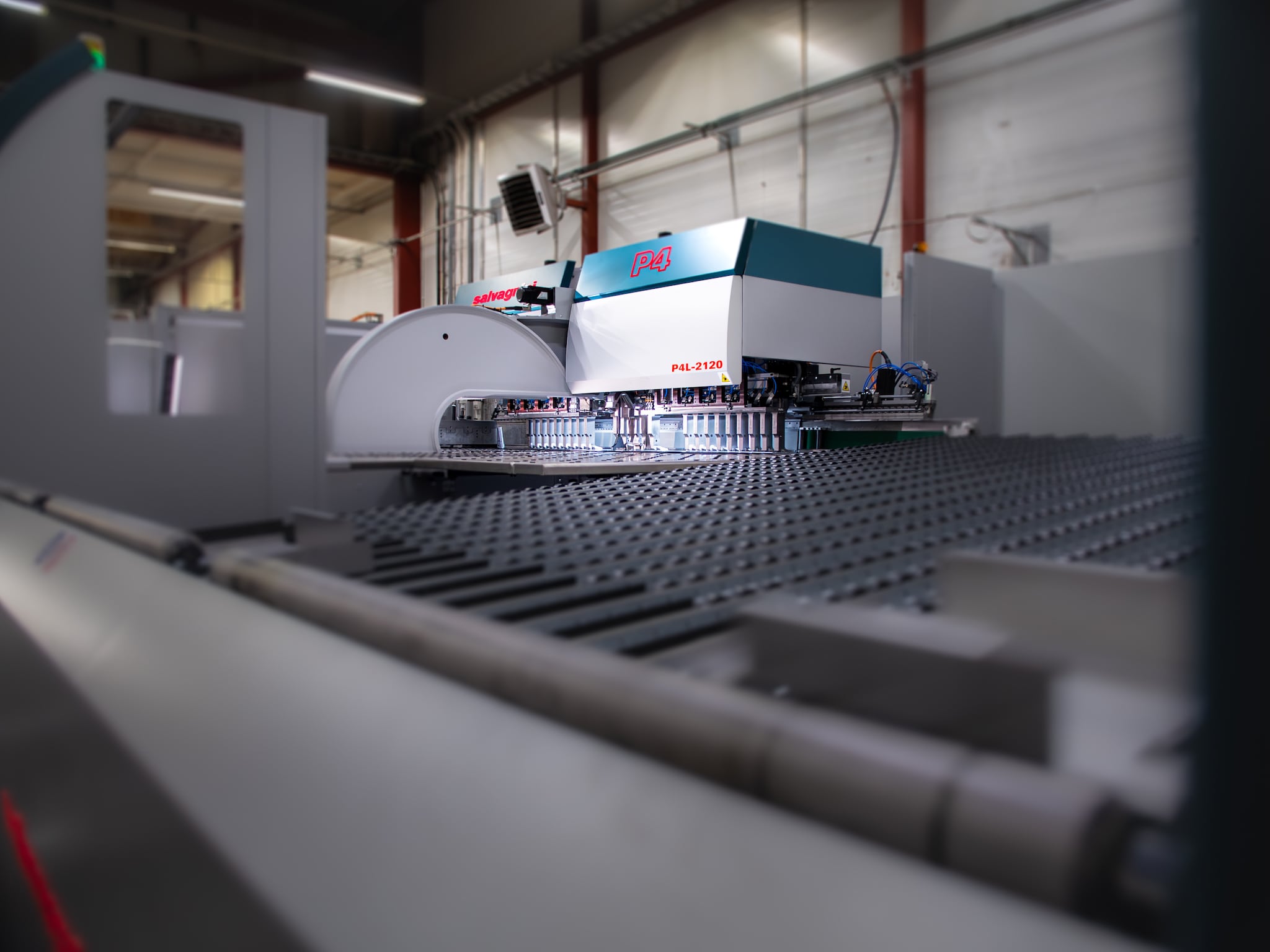

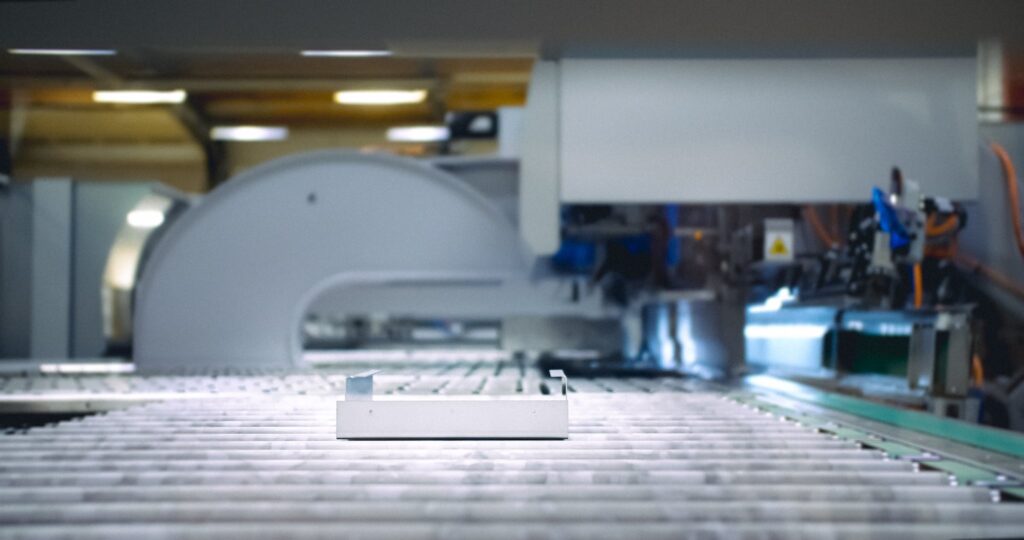

Automated bending with panel bender – Efficient production of curved and complex bends

Our Salvagnini P4 automated panel bender enables precise and rapid bending of sheet metal components. It allows us to manufacture even the most complex geometries in both small and large production batches. Due to its high speed, this technology is ideal for producing panels, enclosures, cabinets, shelving, and profiles.

Key capabilities include:

Maximum efficiency

Our automated panel bender is designed for high-speed production, significantly outperforming manual bending or robotic press brakes. This accelerated process drastically reduces production lead times.

Both small and large batch sizes

We simulate bending programs in a virtual 3D environment to verify manufacturability before production begins. This offline programming allows production to start immediately with zero setup time, making it ideal for both small and large batches.

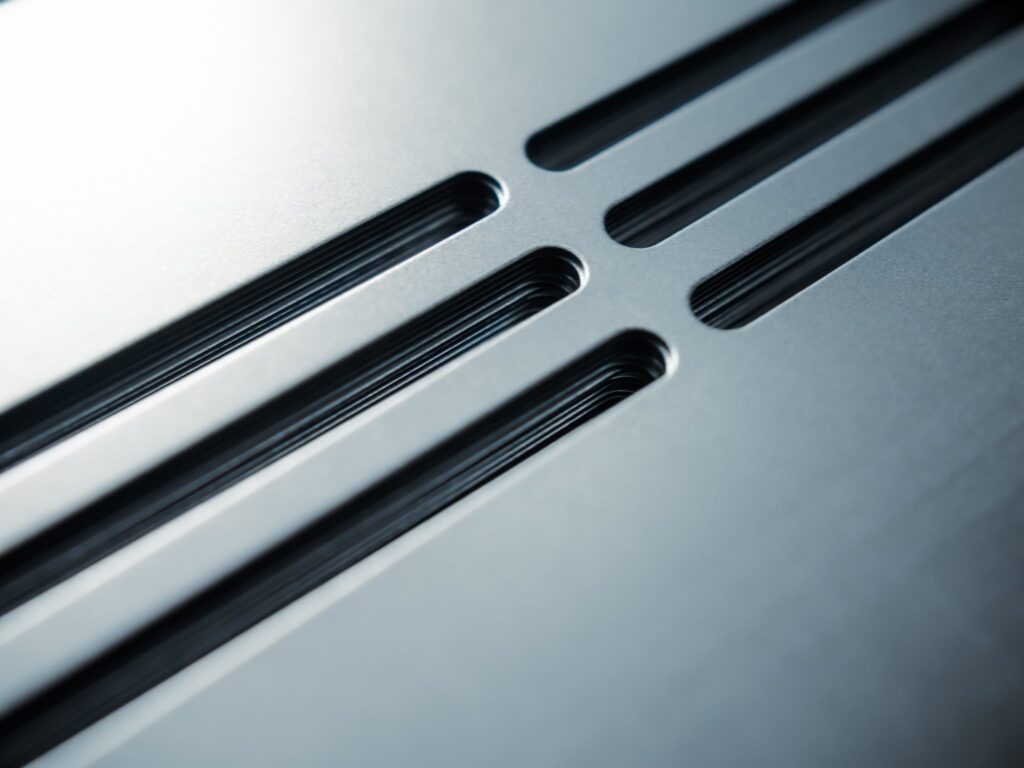

Complex shapes

The machine can execute radius bends, negative bends, and other challenging geometries with excellent repeatability. It handles complex shapes that are difficult or impossible to achieve with traditional methods.

Top-notch consistency

Every bend is performed with extreme precision, eliminating the possibility human error. This automation ensures that every product meets strict dimensional tolerances and quality requirements, from the first piece to the last.

Why choose M-Levy as your manufacturing partner for metal products?

Honest and clear communication

Transparency is the core of our business. We believe that open communication is the foundation of trust and long-term partnership. We keep you fully informed about your project’s progress at every stage. Furthermore, we take a proactive approach: if we identify a more efficient or cost-effective manufacturing method for your product, we will recommend it immediately.

Experienced professionals

Our team consists of top professionals with decades of experience in contract manufacturing. This experience ensures that we understand how to manufacture metal products effectively. If you wish, we are also happy to assist you in designing new products.

Comprehensive services

We provide all the services needed for sheet metal processing under one roof. Our facilities are equipped with automated bending, tube lasers, powder coating lines, and assembly services. This integrated approach saves you time and simplifies your supply chain.

Serving customers across the EU

Our office and factory are located in Muurame, Central Finland, near Jyväskylä, but we have satisfied customers from the West Coast to Eastern Finland. Our logistics network allows us to serve customers efficiently throughout the European Union.

“In general, our cooperation with M-Levy has been seamless.Communication is straightforward and flows smoothly on both sides,” comments Matti Kivimäki, Director Of Purchasing at Harvia

Technical specifications

- Machinery: Automatic panel bender and multiple press brakes of various sizes

- Max. bending force: 240 tons

- Max. bending length (Press Brake): 4000 mm

- Max. bending length (Panel Bender): 2180 mm

Contact us to find the best solution for your needs

Would you like to hear more or request a quote? Submit your request directly online, call us, or send an email. We will answer any questions you may have and will be happy to tell you more about our operations.

Services

Are you seeking a partner who provides not only bending services, but also a comprehensive range of other metal processing capabilities?

Read more about our other capabilities below!

Metal Laser Cutting and Punching

Laser cutting is a precise and rapid method suitable for cutting virtually all metals.

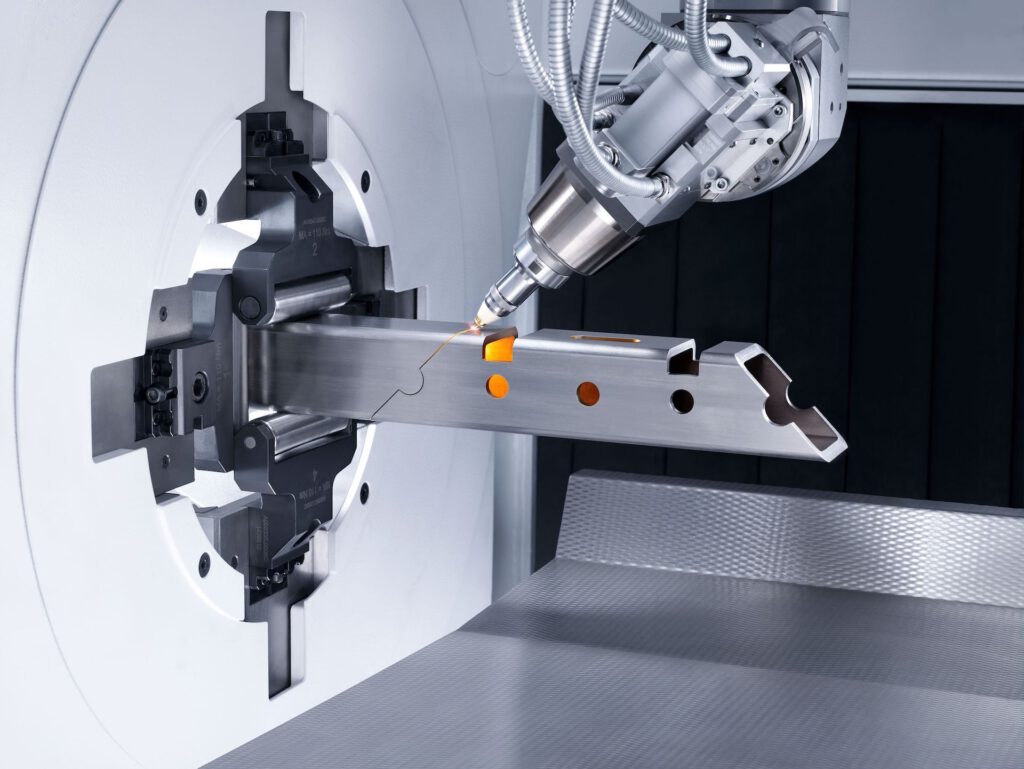

Tube Laser Cutting

Our tube laser machinery is equipped with versatile features designed to meet high expectations for quality, production speed, and cost-effectiveness.

Cylinder Manufacturing

Cylinder manufacturing is a core area of our expertise, backed by decades of experience.

Powder Coating

Powder coating provides a durable and visually appealing finish quickly, efficiently, and in an environmentally friendly manner.

Other Services

We also offer a range of additional processing services, including fastener insertion, eccentric pressing, and various finishing treatments.

Jäikö sinulla vielä jotain kysyttävää?

Ota meihin yhteyttä, niin selvitetään tarpeesi tarkemmin!