Tube laser cutting

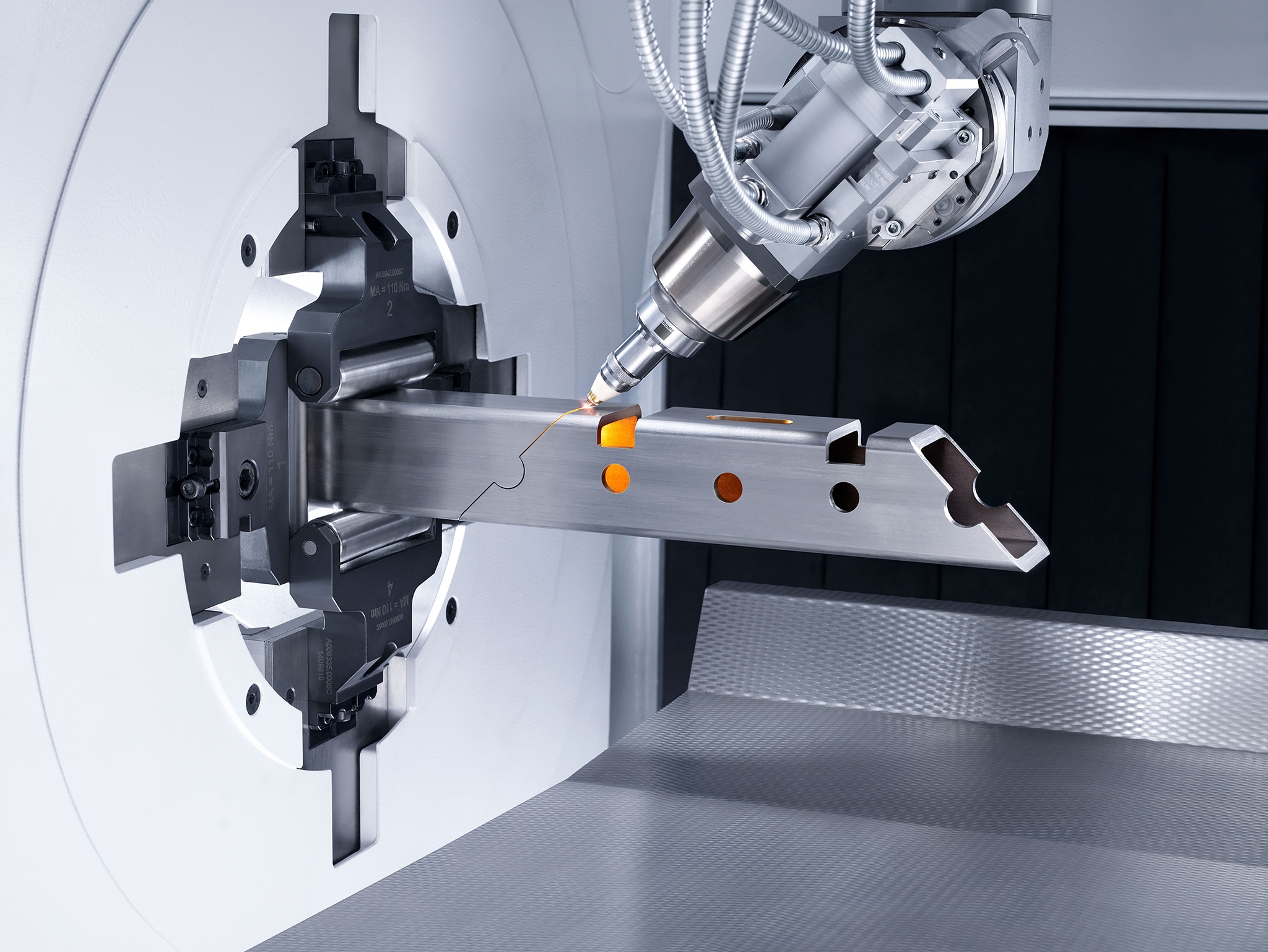

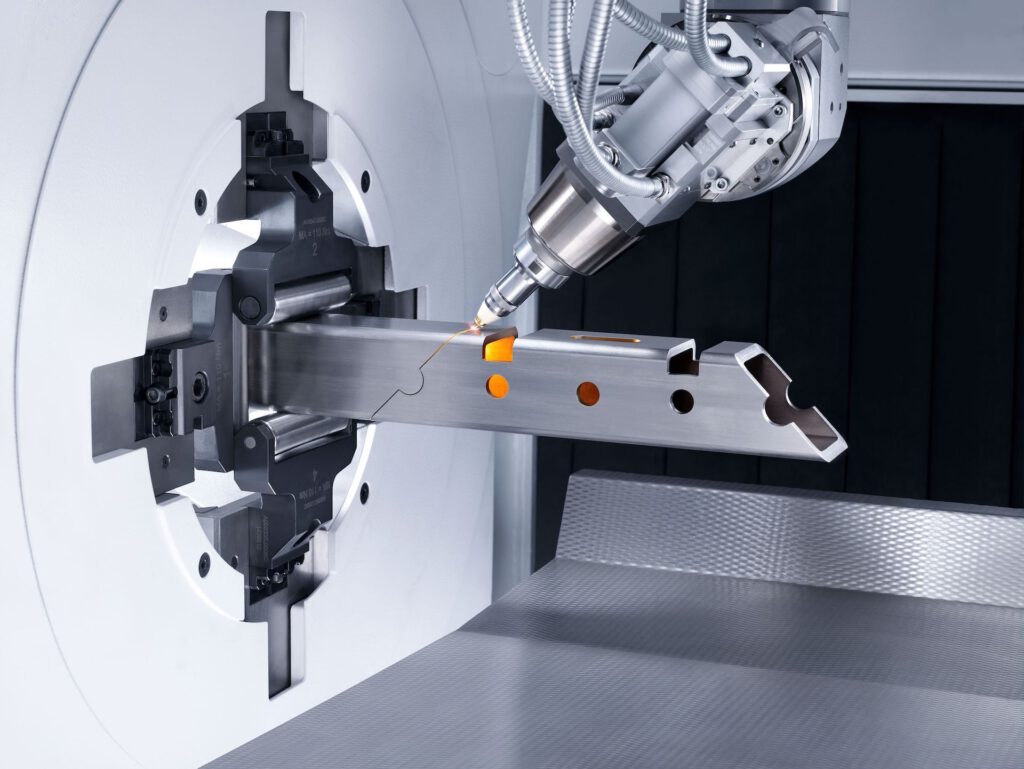

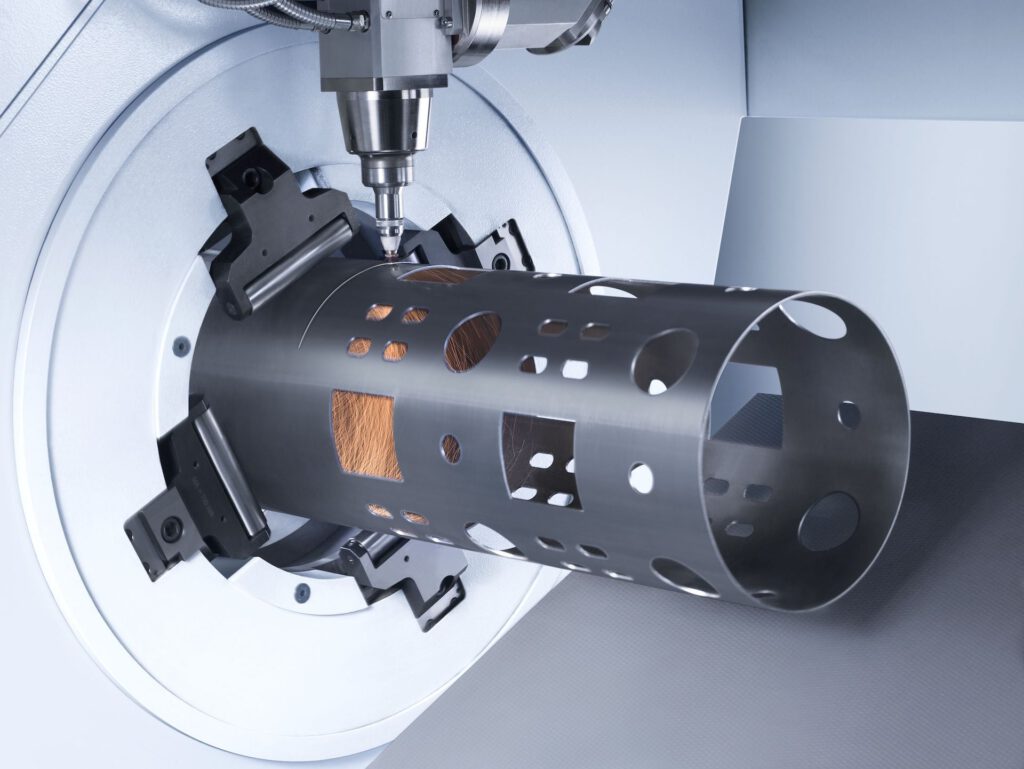

Tube laser cutting enables efficient perforation, slotting, notching, and cutting of tubes and profiles

Do you need fast and reliable tube laser services? At M-Levy, tube laser cutting and metal laser cutting are carried out professionally and on schedule. We cut tubes, hollow sections, and profiles from a wide range of materials, including steel, stainless steel, aluminum, as well as copper and brass.

Our modern 3D tube laser brings exceptional precision and efficiency to your production, significantly speeding up subsequent work phases. We offer comprehensive steel pre-processing and component manufacturing services, as well as full production chain management for your products.

Tube laser programming is fast and efficient, without long setup times or complex tool changes. This makes it an excellent manufacturing method for small series production and prototyping. At M-Levy, we program the tube laser directly from your supplied 3D model (such as a STEP file). If needed, we can also create the models ourselves, even from a hand-drawn sketch.

With our extensive experience, we are happy to support you already in the product development phase, ensuring high-quality metalwork execution!

Benefits of tube laser cutting

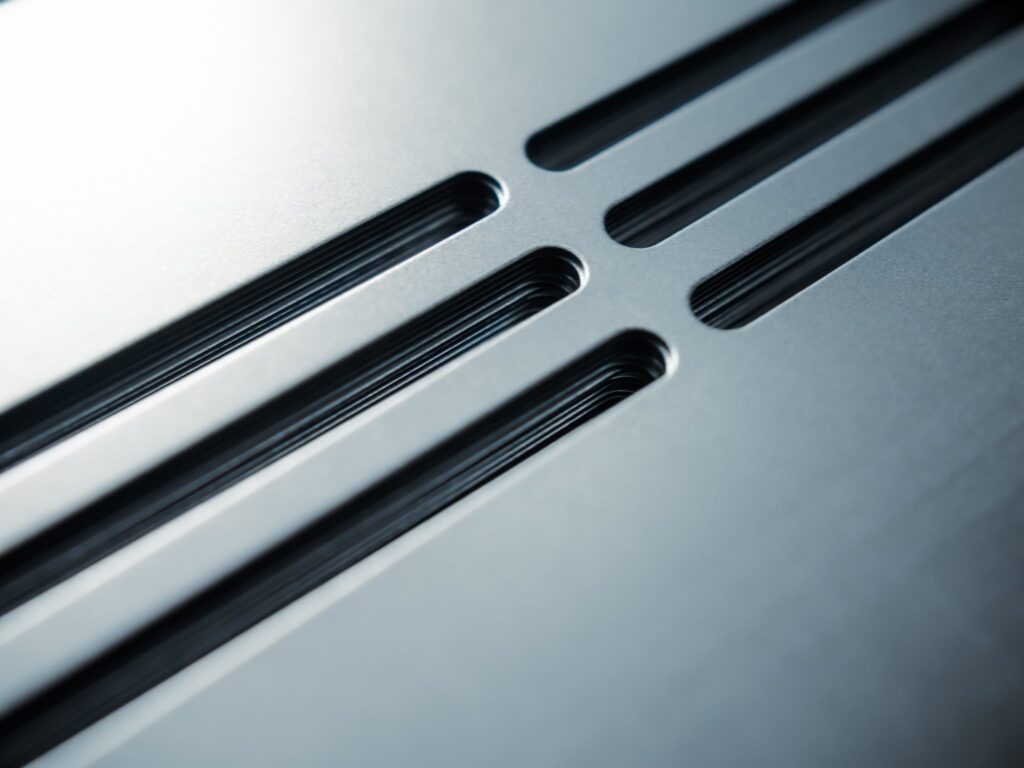

Tube laser cutting is a flexible, efficient, and highly precise processing method. It enables cutting complex geometric shapes in metal tubes and profiles, making it an excellent solution for small series production and prototyping. The process is fully automated, and 3D laser cutting allows for intricate shapes to be cut with outstanding quality.

Additional Benefits:

- Faster and more flexible than traditional methods

- Suitable for complex parts and various profiles

- Enables short setup times and rapid production

- Allows components, such as brackets, to be integrated directly into the workpiece

- Identification markings can be added during production

- Reduces processing steps and material waste

Materials and maximum wall thickness for tube laser cutting:

- Steel: 10 mm

- Stainless Steel: 6 mm

- Aluminum: 6 mm

- Copper: 4 mm

- Brass: 4 mm

Technical Specifications

- Max. Material Length: 6500 mm

- Max. Material Weight: 40 kg/m

- Outer Dimensions (Tube/Profile): Ø12 – Ø254 mm

- Supported Profiles: Round, square, rectangular, U, C, and L profiles, flat bar, oval, and other special profiles

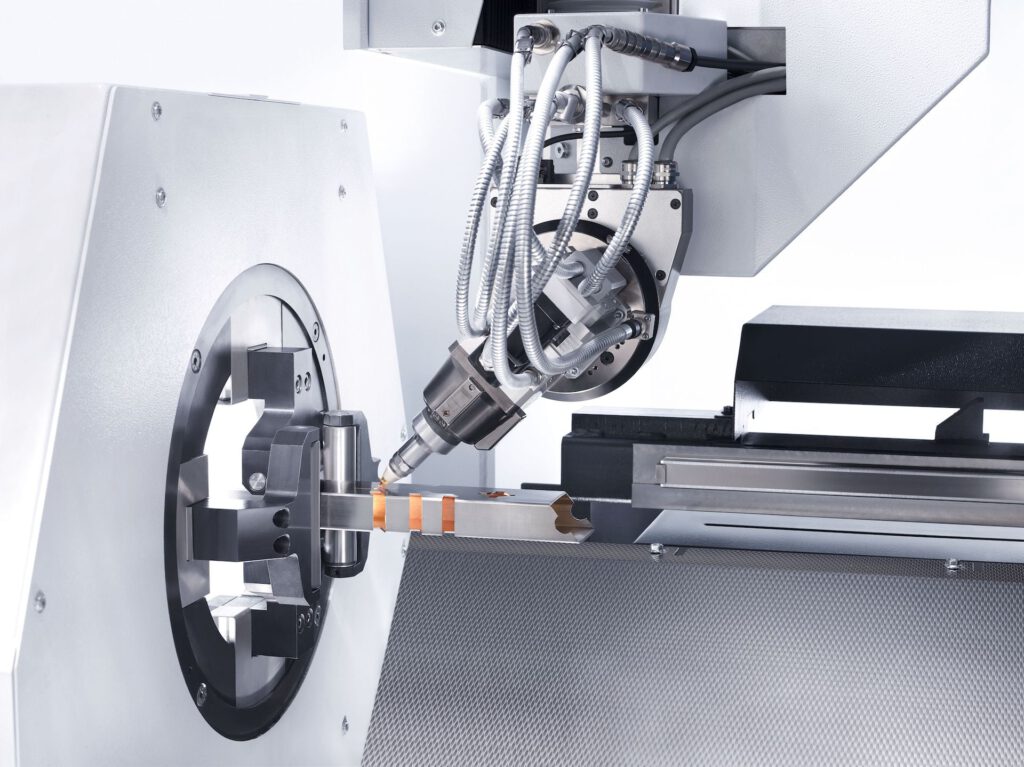

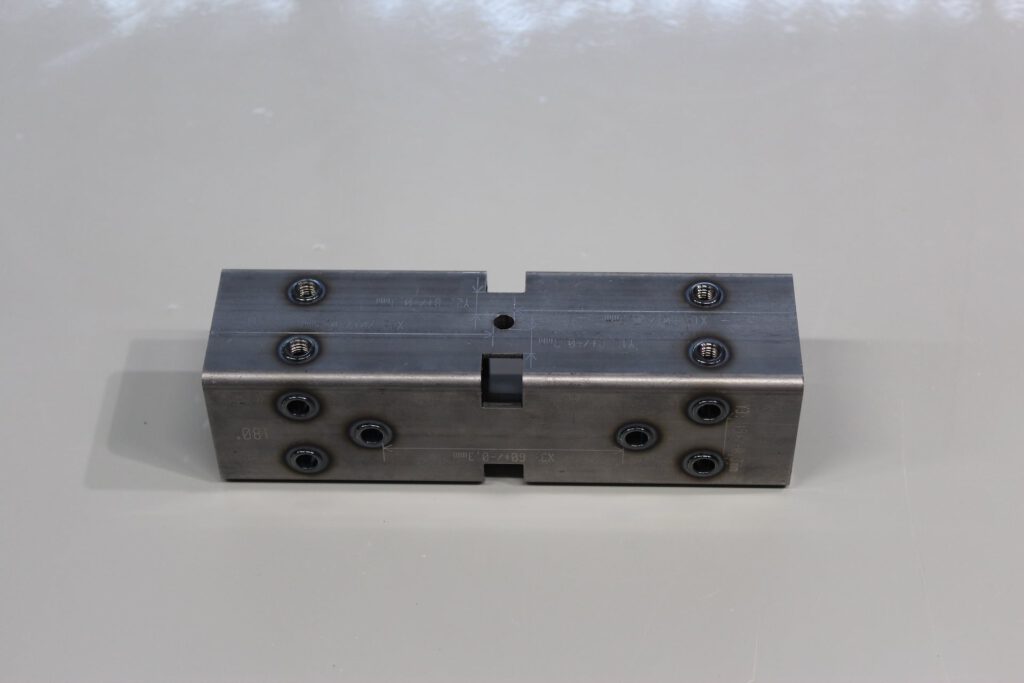

Integrated threading and friction drilling unit

Our tube laser is equipped with an integrated threading and friction drilling unit that significantly enhances production efficiency. Friction drilling technology creates collars that effectively increase the wall thickness for threading. Threads can be applied directly to the collar in the same operation, eliminating the need for additional post-processing steps, such as press-fit, welded, or rivet nuts. This results in a streamlined production process and reduced lead times.

Rotating 3D cutting head

The machine features a rotating 3D cutting head, enabling not just standard cutting and trimming, but also the creation of complex geometries. This includes bevels, miter cuts, and precise weld preparations at angles of up to 45 degrees.

Integrated spatter protection

Our machine includes an integrated spatter protection device (internal spatter guard). This ensures clean, spatter-free inner surfaces for round tubes with an internal diameter of over 40 mm.

Why choose M-Levy as your manufacturing partner for metal products?

Honest and clear communication

Transparency is the core of our business. We believe that open communication is the foundation of trust and long-term partnership. We keep you fully informed about your project’s progress at every stage. Furthermore, we take a proactive approach: if we identify a more efficient or cost-effective manufacturing method for your product, we will recommend it immediately.

Experienced professionals

Our team consists of top professionals with decades of experience in contract manufacturing. This experience ensures that we understand how to manufacture metal products effectively. If you wish, we are also happy to assist you in designing new products.

Comprehensive services

We provide all the services needed for sheet metal processing under one roof. Our facilities are equipped with automated bending, tube lasers, powder coating lines, and assembly services. This integrated approach saves you time and simplifies your supply chain.

Serving customers across the EU

Our office and factory are located in Muurame, Central Finland, near Jyväskylä, but we have satisfied customers from the West Coast to Eastern Finland. Our logistics network allows us to serve customers efficiently throughout the European Union.

M-Levy’s long-term collaboration with Harvia

M-Levy has maintained a long-standing partnership with sauna heater manufacturer Harvia. The comprehensive services provided by M-Levy have played a crucial role in the success of this collaboration. With a diverse range of expertise under one roof, M-Levy offers valuable support in various day-to-day challenges.

“M-Levy has provided us with a wide range of services. As professionals in metalworking, they know exactly what questions to ask when needed, which greatly facilitates smooth cooperation. They also visit our site when necessary to ensure we get the right solution,” says Tuomo Kakkonen, Production Director at Harvia’s Muurame sauna heater factory.

Services

Contact us to find the best solution for your needs

Would you like to learn more or request a quote? Submit your request directly online, call us, or send an email, and we will be happy to answer any questions you may have – contact us.

Are you looking for a partner who offers not only tube laser cutting but also a wide range of other metalworking services? Read more about our other capabilities below!

Metal Laser Cutting and Punching

Laser cutting is a precise and rapid method suitable for cutting virtually all metals.

Cylinder manufacturing

Cylinder manufacturing is a core area of our expertise, backed by decades of experience.

Powder coating

Powder coating provides a durable and visually appealing finish quickly, efficiently, and in an environmentally friendly manner.

Other services

We also offer a range of additional processing services, including fastener insertion, eccentric pressing, and various finishing treatments.

Do you still have questions?

Contact us, and let’s discuss your needs in more detail!